A serpentine belt is a long, continuous belt in car engines that drives multiple peripheral devices. It powers components like the alternator, water pump, and air conditioning compressor.

The serpentine belt is essential for the smooth operation of various engine components. It is a single, continuous belt that winds around multiple pulleys. This design makes it more efficient and easier to maintain compared to older systems with multiple belts.

Regular inspection and timely replacement of the serpentine belt are crucial. A worn or damaged belt can lead to engine failure or the malfunctioning of key systems. Always consult your vehicle’s manual for the recommended maintenance schedule. A well-maintained serpentine belt ensures optimal engine performance and longevity.

Credit: en.wikipedia.org

The Heartbeat Of Your Engine: The Serpentine Belt

The serpentine belt is a crucial part of your car’s engine. It powers various engine components, ensuring smooth operation. Without it, many essential systems would fail.

Why It’s More Than Just A Belt

The serpentine belt powers the alternator, power steering pump, and air conditioning. It also drives the water pump, which cools the engine.

A single belt running multiple components makes it efficient. This design reduces wear and tear compared to older multiple belt systems.

| Component | Function |

|---|---|

| Alternator | Generates electricity for the car |

| Power Steering Pump | Makes steering easier |

| Air Conditioning | Keeps the interior cool |

| Water Pump | Cools the engine |

Signs Of A Failing Serpentine Belt

- Squealing Noises: A high-pitched noise can indicate wear.

- Power Loss: If power steering fails, check the belt.

- Overheating: A worn belt can cause the engine to overheat.

- Visible Cracks: Inspect the belt for cracks and frays.

Regular inspection and maintenance of the serpentine belt is vital. Always replace it as recommended by your car’s manufacturer.

When To Replace Your Serpentine Belt

The serpentine belt is essential for your car’s operation. It powers various components like the alternator, power steering pump, and air conditioning compressor. Knowing when to replace your serpentine belt can save you from unexpected breakdowns and costly repairs.

Mileage Guidelines

Most manufacturers recommend replacing the serpentine belt every 60,000 to 100,000 miles. Always check your vehicle’s manual for specific guidelines.

| Mileage | Action |

|---|---|

| 0-60,000 miles | Inspect for wear |

| 60,000-100,000 miles | Replace if necessary |

| 100,000+ miles | Replace immediately |

Visual And Auditory Clues

Identifying wear signs can help you replace the belt at the right time.

- Cracks and Frays: Check for visible cracks or frayed edges.

- Squealing Noise: A high-pitched noise can signal a worn belt.

- Glazing: If the belt looks shiny, it may be slipping.

- Loss of Power: Diminished power in accessories can indicate belt issues.

Regular inspections ensure your serpentine belt stays in good condition. Pay attention to these mileage guidelines and visual and auditory clues to keep your vehicle running smoothly.

Consequences Of Ignoring Serpentine Belt Replacement

Ignoring a serpentine belt replacement can lead to serious issues. This component is vital for many engine functions. When it fails, your car may face several problems. Here are some key consequences:

Engine Overheating

The serpentine belt helps the engine stay cool. It drives the water pump, which circulates coolant. Without it, the engine can overheat quickly. This can lead to severe damage.

- Coolant circulation stops.

- Engine components get too hot.

- Risk of engine failure increases.

Loss Of Power Steering

The serpentine belt also powers the power steering pump. Without it, steering becomes difficult. This can be dangerous, especially at high speeds or during turns.

- Steering becomes hard.

- Driving becomes unsafe.

- Risk of accidents increases.

Alternator Failure

The alternator charges the car’s battery. The serpentine belt drives the alternator. If the belt breaks, the battery won’t charge. This can leave you stranded.

| Problem | Effect |

|---|---|

| Battery not charging | Car won’t start |

| Electrical systems fail | Lights and radio stop working |

| Alternator damage | Costly repairs |

Diy Replacement: Is It Right For You?

Replacing a serpentine belt yourself can save money and time. It can be a rewarding experience. But is it the right choice for you? Let’s dive into the details. Understand the tools and steps involved. This will help you make an informed decision.

Tools You’ll Need

- Wrench set – Essential for loosening bolts.

- Belt tensioner tool – Helps release tension.

- Socket set – For various bolt sizes.

- Replacement belt – Make sure it’s the right fit.

- Gloves – Protect your hands.

- Safety glasses – Shield your eyes.

Step-by-step Guide

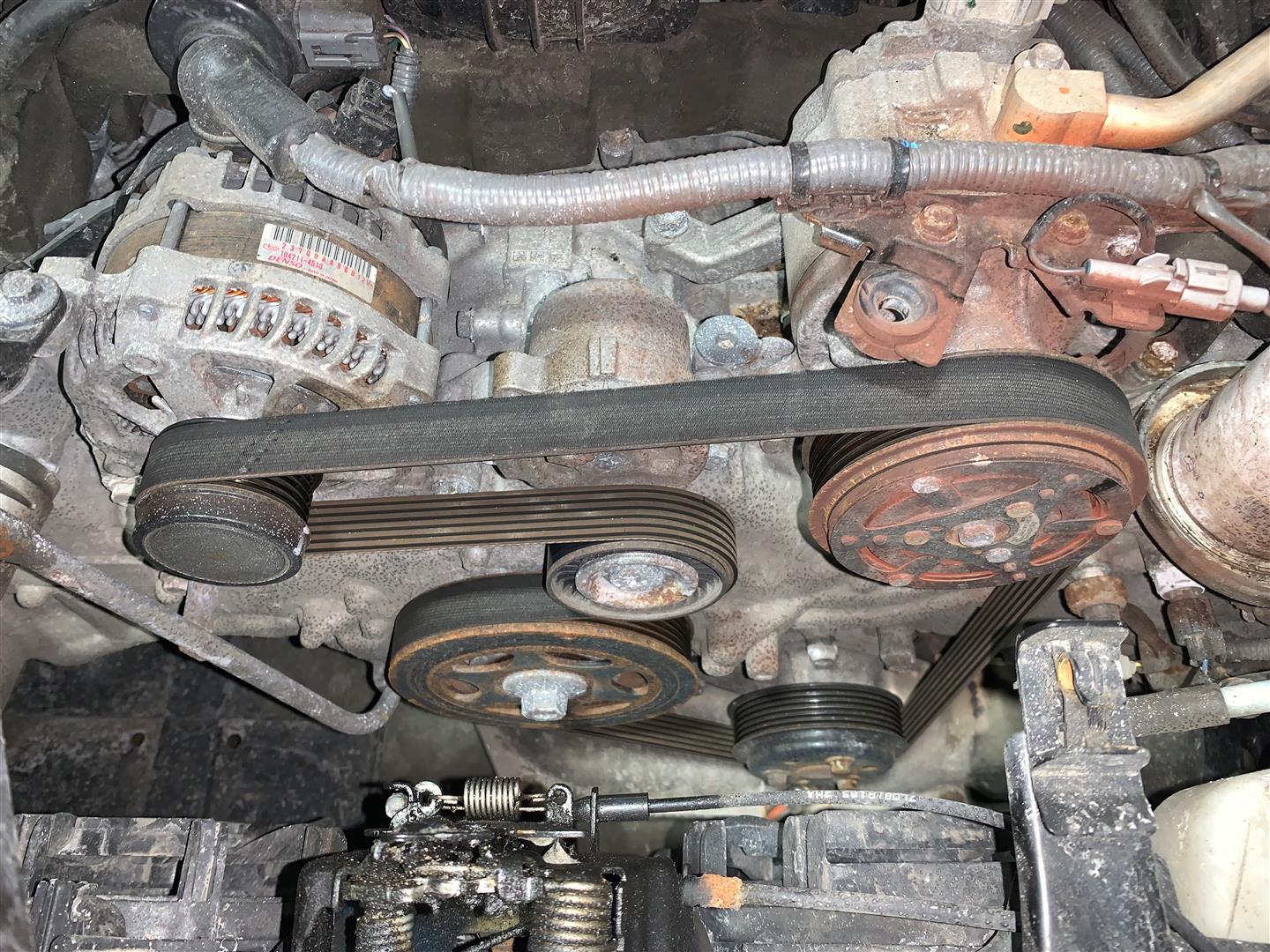

- Locate the belt – Check the engine bay for the serpentine belt.

- Note the belt path – Draw a diagram or take a picture.

- Release tension – Use the belt tensioner tool to loosen the belt.

- Remove the old belt – Slide it off the pulleys carefully.

- Compare the belts – Ensure the new belt matches the old one.

- Install the new belt – Follow the belt path diagram.

- Apply tension – Use the tensioner tool to tighten the belt.

- Check alignment – Ensure the belt sits properly on pulleys.

- Start the engine – Run the engine and observe the belt.

Deciding to replace the serpentine belt yourself can be empowering. Ensure you have the right tools and knowledge. If unsure, consulting a professional is always a good option. Happy wrenching!

Professional Replacement: What To Expect

Replacing a serpentine belt is crucial for your vehicle’s performance. A professional replacement ensures the job is done correctly. This section covers what you can expect during the process.

Choosing The Right Mechanic

Finding the right mechanic is the first step. Experience and certification are key factors. Look for a mechanic with good reviews. Check their certifications and ask about their experience with serpentine belts.

Ask friends and family for recommendations. Online reviews can also help. Ensure the mechanic has experience with your vehicle make and model.

Cost And Time Estimates

The cost of replacing a serpentine belt varies. It depends on your vehicle and location. On average, expect to pay between $75 and $200.

| Service | Cost | Time |

|---|---|---|

| Serpentine Belt Replacement | $50 – $100 | 30 minutes |

| Labor | $25 – $100 | 30 – 60 minutes |

Labor costs can vary. They depend on the mechanic’s rate and time needed. Always get a written estimate before agreeing to the work.

- Expect the job to take about an hour.

- Make sure to ask for a warranty on the work.

- Keep your receipt for future reference.

Replacing a serpentine belt can save you from bigger issues. It’s worth investing in professional help.

Selecting The Right Serpentine Belt

Choosing the right serpentine belt is crucial for your car’s performance. The belt drives essential components such as the alternator, power steering pump, and air conditioning compressor. Selecting the correct belt ensures these parts function seamlessly, avoiding potential breakdowns.

Oem Vs Aftermarket

Original Equipment Manufacturer (OEM) belts are made by the car’s manufacturer. These belts fit perfectly and meet strict quality standards. OEM belts are often more expensive but provide reliability and durability.

Aftermarket belts are produced by third-party companies. They may cost less but vary in quality. Some aftermarket belts match OEM standards, while others may not. Checking reviews and brand reputation helps in selecting a good aftermarket belt.

| Type | Pros | Cons |

|---|---|---|

| OEM |

|

|

| Aftermarket |

|

|

Material And Durability Considerations

Material impacts the belt’s durability and performance. Common materials include neoprene and ethylene propylene diene monomer (EPDM). Neoprene belts are older technology and may wear out faster. EPDM belts last longer and perform better under extreme conditions.

Durability is a key factor. A durable belt reduces the need for frequent replacements. High-quality belts resist cracking, fraying, and stretching. Checking the belt’s warranty can also indicate its durability. Look for belts with a longer warranty period.

- Neoprene: Suitable for standard driving conditions.

- EPDM: Ideal for extreme conditions and longer lifespan.

Choosing the right material and ensuring durability helps avoid unexpected failures. It also ensures your car’s components operate smoothly, enhancing overall performance.

Common Mistakes To Avoid During Replacement

Replacing a serpentine belt might seem simple. Yet, many people make errors. Avoiding these mistakes ensures your vehicle runs smoothly.

Incorrect Tension

Incorrect tension on a serpentine belt can cause problems. Too tight and it may wear out quickly. Too loose and it may slip off.

To set the correct tension:

- Use a tension gauge tool

- Refer to your vehicle’s manual

- Check the belt for the right amount of give

Correct tension ensures the belt lasts longer and works efficiently.

Misalignment And Routing Errors

Misalignment and routing errors are common during replacement. Proper alignment is crucial for the belt to work correctly.

To avoid misalignment:

- Follow the belt routing diagram

- Ensure all pulleys are in a straight line

- Double-check the belt’s path

Routing errors can lead to severe engine damage. Always verify the belt’s path twice. A correctly routed belt ensures smooth operation.

| Common Mistake | Effect |

|---|---|

| Incorrect Tension | Causes belt wear or slipping |

| Misalignment | Leads to inefficient operation |

| Routing Errors | Can damage the engine |

Troubleshooting Post-replacement Issues

Replacing the serpentine belt can sometimes lead to new issues. Identifying and fixing these problems ensures your vehicle runs smoothly. Here are common post-replacement problems and how to troubleshoot them effectively.

Squealing Noises

Squealing noises after replacing the serpentine belt can be annoying. They usually indicate a misalignment or a tension problem.

- Check Belt Alignment: Use a straight edge to verify the belt is aligned.

- Inspect Pulleys: Ensure all pulleys are in good condition and aligned.

- Adjust Tension: Ensure the belt has the correct tension. Too tight or too loose can cause noise.

Rapid Wear And Tear

Rapid wear and tear on a new serpentine belt indicates underlying issues. Address these quickly to avoid further damage.

| Issue | Possible Cause | Solution |

|---|---|---|

| Fraying Edges | Misaligned pulleys | Realign pulleys |

| Cracks and Splits | Old or damaged pulleys | Replace pulleys |

| Glazing | Excessive heat | Check cooling system |

Addressing these issues helps extend the life of your serpentine belt. Regular checks and maintenance are crucial for vehicle health.

Maintaining Your New Serpentine Belt

A new serpentine belt keeps your engine running smoothly. It drives essential components like the alternator, power steering pump, and air conditioning compressor. Proper maintenance of your serpentine belt ensures optimal performance and extends its lifespan.

Regular Inspections

Regular inspections are crucial for maintaining your serpentine belt. Check for signs of wear and tear every month. Look for cracks, fraying, or glazing on the belt surface.

- Inspect for cracks or splits.

- Check for fraying edges.

- Look for a glossy or glazed finish.

If you notice any of these issues, replace the belt immediately. Regular inspections help prevent unexpected breakdowns.

Preventive Measures

Taking preventive measures can extend the life of your serpentine belt. Keep the belt clean and free from oil or coolant leaks. Ensure proper tension to avoid slipping or excessive wear.

| Preventive Measure | Description |

|---|---|

| Clean the Belt | Wipe off any oil or coolant. |

| Check Tension | Ensure the belt is neither too tight nor too loose. |

| Inspect Pulleys | Check for misalignment or wear. |

Following these preventive measures ensures your serpentine belt performs optimally. Proper maintenance saves you from costly repairs and keeps your vehicle running smoothly.

Credit: www.louscarcare.com

The Environmental Impact Of Serpentine Belt Disposal

Serpentine belts are essential in vehicle engines. They power many components. These belts wear out and need replacement. Improper disposal of old belts harms the environment. Recycling and eco-friendly disposal can reduce this impact.

Recycling Old Belts

Recycling old serpentine belts is a responsible choice. Many parts of the belt are recyclable. Rubber and metal components can be reused. Recycling centers accept these materials. They process and repurpose them.

To recycle, first clean the old belt. Remove any dirt or oil. Next, take it to a local recycling center. Some auto shops also offer recycling services. They ensure the belt materials are reused efficiently.

| Material | Reuse Method |

|---|---|

| Rubber | Repurposed into new products |

| Metal | Melted and reused in manufacturing |

Eco-friendly Disposal Tips

If recycling is not an option, consider eco-friendly disposal methods. Here are some tips to help:

- Avoid landfills: Dispose of belts at designated centers.

- Repurpose: Use old belts in creative DIY projects.

- Donate: Some organizations accept old belts for reuse.

Disposing of serpentine belts responsibly protects the environment. It reduces waste and promotes sustainability.

Future Innovations In Serpentine Belt Technology

The serpentine belt plays a crucial role in your vehicle’s engine. It powers multiple components like the alternator, water pump, and air conditioning. Innovations in serpentine belt technology are making these belts more efficient and durable.

Material Advancements

New materials are being developed for serpentine belts. These materials promise better performance and durability. Kevlar and EPDM (Ethylene Propylene Diene Monomer) are some examples.

These materials offer several benefits:

- Higher strength to withstand more stress

- Improved heat resistance to endure high temperatures

- Enhanced flexibility for better belt alignment

Manufacturers are also experimenting with nano-materials. These materials can increase belt efficiency and reduce wear.

Longevity Improvements

Longevity improvements are another focus area. Modern serpentine belts are designed to last longer. Some new belts can last up to 100,000 miles or more.

Several factors contribute to this increased longevity:

- Advanced manufacturing techniques for better belt quality

- Improved tensioners to keep the belt properly aligned

- Better materials that resist cracking and fraying

Regular maintenance also plays a role. Keeping the belt clean and properly tensioned can extend its life.

| Feature | Benefit |

|---|---|

| Kevlar Material | High strength and durability |

| EPDM Rubber | Heat resistance and flexibility |

| Nano-materials | Increased efficiency and reduced wear |

Credit: docable.com

Case Studies: Real-life Serpentine Belt Scenarios

Serpentine belts are crucial for your car’s operation. Real-life scenarios show their importance. Learn from success stories and failures.

Success Stories

Many drivers have avoided disasters by checking their serpentine belts. Regular maintenance saves lives and money. Let’s look at some success stories.

- John’s Quick Check: John always checks his car before long trips. He noticed wear on his belt. Replacing it saved him from a breakdown.

- Susan’s Routine Maintenance: Susan follows a strict maintenance schedule. Her mechanic found a small crack. Fixing it early prevented bigger issues.

- Mike’s Pre-Road Trip Inspection: Mike inspects his belt before every road trip. He once found a loose belt, tightened it, and avoided engine overheating.

Lessons Learned From Failures

Not everyone is lucky. Some people ignore warning signs. Here are lessons learned from serpentine belt failures.

- Tim’s Ignored Squeal: Tim heard a squeal but ignored it. His belt snapped on the highway. He faced expensive repairs and towing charges.

- Anna’s Overdue Replacement: Anna knew her belt was old. She delayed replacing it. It broke while she was driving, causing her engine to overheat.

- Dave’s Overlooked Inspection: Dave never inspected his belt. It wore out and failed. He was stranded for hours waiting for help.

| Scenario | Outcome |

|---|---|

| John’s Quick Check | Prevented breakdown |

| Susan’s Routine Maintenance | Avoided bigger issues |

| Mike’s Pre-Road Trip Inspection | Prevented engine overheating |

| Tim’s Ignored Squeal | Faced expensive repairs |

| Anna’s Overdue Replacement | Engine overheated |

| Dave’s Overlooked Inspection | Stranded for hours |

Frequently Asked Questions

What Does A Serpentine Belt Do?

A serpentine belt powers multiple car components like the alternator, power steering pump, and air conditioning compressor.

How Long Does A Serpentine Belt Last?

A serpentine belt typically lasts between 60,000 to 100,000 miles, depending on driving conditions and maintenance.

What Are Signs Of A Bad Serpentine Belt?

Common signs include squeaking noises, visible cracks, power steering failure, and engine overheating.

Can I Drive With A Broken Serpentine Belt?

Driving with a broken serpentine belt is dangerous. It can lead to engine overheating and loss of power steering.

How Much Does A Serpentine Belt Replacement Cost?

Serpentine belt replacement costs range from $50 to $200, including parts and labor, depending on the vehicle type.

Conclusion

A healthy serpentine belt is crucial for your vehicle’s performance. Regular inspections can prevent unexpected breakdowns. Replacing it on time saves you from costly repairs. Keep your vehicle running smoothly by giving attention to this vital component. Your car will thank you with better reliability and efficiency.