A crankshaft sensor monitors the position and rotational speed of the crankshaft. It is vital for engine management.

The crankshaft sensor plays a crucial role in modern engines. It helps the engine control unit (ECU) determine the precise timing for fuel injection and ignition. This sensor ensures optimal engine performance, fuel efficiency, and reduced emissions. By providing accurate data on the crankshaft’s position and speed, the sensor aids in smooth engine operation.

Faulty crankshaft sensors can lead to engine misfires, poor fuel economy, and stalling. Regular maintenance and timely replacement of the crankshaft sensor are essential for vehicle reliability. Understanding its function helps in diagnosing engine issues effectively. This small but significant component is fundamental for vehicle performance.

Credit: en.wikipedia.org

The Heart Of The Matter: Crankshaft Sensor Basics

The crankshaft sensor is crucial for your car’s engine. It helps monitor the position and speed of the crankshaft. This sensor is vital for engine timing and fuel injection. Understanding its function can help maintain your vehicle.

Why It Matters

A faulty crankshaft sensor can cause engine issues. Your car may have trouble starting. It may also stall unexpectedly. The sensor ensures the engine runs smoothly. Without it, the engine control unit (ECU) can’t adjust the fuel injection or ignition timing.

| Issue | Effect |

|---|---|

| Starting problems | Car may not start |

| Stalling | Engine may shut off suddenly |

| Poor performance | Reduced power and efficiency |

How It Works

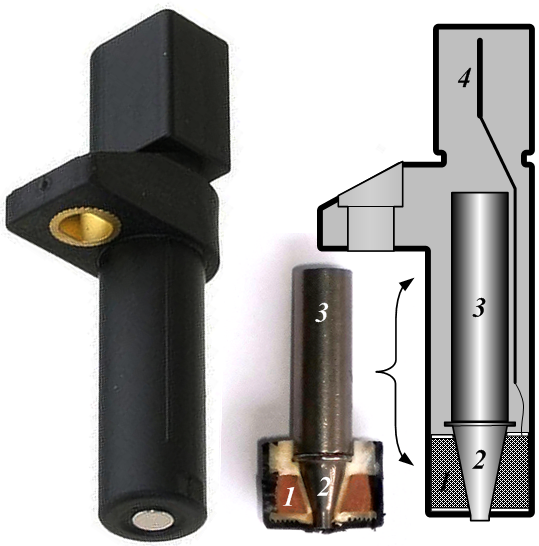

The crankshaft sensor uses a magnetic or Hall effect sensor. It detects the position and speed of the crankshaft. This data is sent to the ECU. The ECU uses this information to control fuel injection and spark timing.

- Magnetic sensors generate a signal as the crankshaft turns.

- Hall effect sensors produce a voltage based on magnetic fields.

Both types provide accurate data to the ECU. This ensures optimal engine performance. Regular checks and maintenance are essential. A well-functioning crankshaft sensor keeps your engine running efficiently.

Common Symptoms Of Failure

The crankshaft sensor is crucial for your car’s engine. It monitors the position and speed of the crankshaft. When this sensor fails, your car can face many issues. Here, we discuss common symptoms of a failing crankshaft sensor.

Engine Misfires

One common symptom is engine misfires. The sensor sends inaccurate signals to the engine control unit (ECU). This leads to improper fuel injection and spark timing. As a result, the engine may misfire.

Engine misfires can cause rough idling. You may notice a jerking motion while driving. This can also lead to a loss of power. If ignored, it can damage other engine components.

Starting Difficulties

Another symptom is starting difficulties. The crankshaft sensor helps start the engine. If it fails, the engine may not start at all. It can also cause long cranking times.

You may hear the engine turning over but not starting. This could be a sign of a failing crankshaft sensor. Always check the sensor if you face starting issues.

Diagnostic Tools You’ll Need

Checking your crankshaft sensor needs the right tools. This guide helps you understand them. You will learn about the multimeter and scanner codes. These tools make the job easier and faster.

Multimeter Magic

A multimeter is crucial for testing the crankshaft sensor. It measures voltage, resistance, and continuity. Here’s how to use it:

- Set the multimeter to the correct setting.

- Connect the probes to the sensor terminals.

- Read the values on the display.

Make sure to check the values against the manufacturer’s specifications. Incorrect values might mean a faulty sensor.

Scanner Codes

A scanner tool reads error codes from the vehicle’s computer. These codes can tell you if the crankshaft sensor is malfunctioning. Follow these steps:

- Plug the scanner into the OBD-II port.

- Turn on the vehicle’s ignition.

- Read the error codes from the scanner.

Error codes related to the crankshaft sensor usually start with “P”. For example, P0335 indicates a sensor problem. The scanner tool saves time and helps pinpoint issues quickly.

Step-by-step Troubleshooting Guide

Is your engine running rough? The crankshaft sensor might be the problem. Follow this step-by-step troubleshooting guide to diagnose and fix the issue.

Visual Inspection

Start with a visual inspection. Look for any obvious damage to the sensor.

- Check for cracks or broken wires.

- Ensure the sensor is securely mounted.

- Look for oil leaks around the sensor.

If you find any physical damage, replace the sensor. If not, proceed to electrical testing.

Electrical Testing

Use a multimeter for electrical testing. Follow these steps:

- Set the multimeter to resistance mode.

- Disconnect the sensor’s electrical connector.

- Measure the resistance between the sensor’s terminals.

Compare the reading to the manufacturer’s specifications. If the resistance is out of range, the sensor is faulty.

| Condition | Action |

|---|---|

| Resistance within range | Sensor is good |

| Resistance out of range | Replace the sensor |

If the resistance is within the range, proceed to voltage testing. Reconnect the sensor and set the multimeter to voltage mode.

- Start the engine.

- Measure the voltage at the sensor’s connector.

Compare this voltage to the manufacturer’s specifications. If the voltage is incorrect, the sensor is faulty.

Interpreting Diagnostic Trouble Codes (dtcs)

Understanding Diagnostic Trouble Codes (DTCs) is crucial for maintaining your vehicle. These codes help identify issues with various sensors, including the crankshaft sensor. By learning to interpret these codes, you can quickly address problems and keep your car running smoothly.

Common Codes

The crankshaft sensor is essential for engine management. Common DTCs related to this sensor include P0335, P0336, and P0337. Each code points to specific issues that need addressing.

What They Mean

| Code | Description | Possible Causes |

|---|---|---|

| P0335 | Crankshaft Position Sensor “A” Circuit |

|

| P0336 | Crankshaft Position Sensor “A” Range/Performance |

|

| P0337 | Crankshaft Position Sensor “A” Low Input |

|

Each code provides valuable information about your vehicle’s crankshaft sensor. Addressing these issues promptly can prevent further damage and costly repairs. Understanding DTCs empowers you to maintain your vehicle effectively.

The Multimeter Mastery

Testing your crankshaft sensor can seem tricky. But with a multimeter, it’s simple. This guide will help you set up and read the results. You’ll be a pro in no time!

Setting Up

To start, gather your tools. You’ll need a multimeter, some jumper wires, and your car’s manual.

- Turn off your car’s engine.

- Locate the crankshaft sensor.

- Disconnect the sensor’s connector.

Set your multimeter to the resistance or ohms setting. Attach the multimeter leads to the sensor terminals. Make sure you have a good connection. This setup is crucial for accurate readings.

Reading The Results

Once everything is set up, it’s time to read the results. Look at the multimeter display.

- If the reading is within the specified range, your sensor is good.

- If the reading is too high or low, the sensor may be faulty.

Refer to your car’s manual for the exact resistance range. This ensures you’re comparing the results correctly. Accuracy is key to diagnosing issues.

When To Call A Professional

The crankshaft sensor is a vital component in your vehicle’s engine management system. It monitors the position and rotational speed of the crankshaft. This data ensures optimal engine performance and efficiency. While some issues can be resolved with basic tools, certain situations require professional intervention.

Complex Issues

Crankshaft sensor problems can sometimes be complex. Issues like electrical faults, sensor misalignment, or internal engine damage often need expert attention. A professional mechanic has the skills to diagnose and fix these problems accurately. They use advanced diagnostic tools to pinpoint the exact cause.

Attempting to resolve these issues on your own can lead to further damage. Misdiagnosis can result in unnecessary repairs and increased costs. Professionals ensure that the repair is done correctly the first time. This saves both time and money in the long run.

Safety Concerns

Working on your vehicle can pose safety risks. The crankshaft sensor is located in a confined space near moving engine parts. Handling it without proper knowledge and tools can be dangerous. Professionals have the training to manage these risks effectively.

Another safety concern is electrical hazards. The crankshaft sensor is part of the vehicle’s electrical system. Mishandling electrical components can cause short circuits or other damage. Professionals are equipped to handle these risks safely.

| Issue | Reason to Call a Professional |

|---|---|

| Electrical Faults | Requires specialized diagnostic tools and expertise |

| Sensor Misalignment | Needs precise adjustment to avoid engine problems |

| Internal Engine Damage | Complex issue that can cause further damage if misdiagnosed |

- Professional tools ensure accurate diagnosis.

- Safety is a priority with trained experts.

- Correct repairs save time and money.

- Identify complex issues like electrical faults.

- Ensure safe handling of engine components.

- Use professional tools for precise adjustments.

Credit: www.amazon.com

Replacing The Crankshaft Sensor

Replacing the crankshaft sensor can seem daunting, but it is doable. This guide walks you through the necessary steps to replace the crankshaft sensor. Follow these steps to ensure your vehicle runs smoothly.

Choosing The Right Part

First, ensure you have the correct crankshaft sensor for your vehicle. Consult your vehicle’s manual for the part number. You can also check online databases for compatibility.

Here are some tips to help you choose the right part:

- OEM parts are usually the best choice.

- Check customer reviews for aftermarket options.

- Verify the return policy in case the part does not fit.

Installation Guide

Once you have the right sensor, you can start the installation. Follow these steps:

- Disconnect the battery to prevent any electrical shorts.

- Locate the crankshaft sensor usually near the engine block.

- Remove the old sensor by unscrewing the bolts.

- Install the new sensor carefully, ensuring it fits snugly.

- Reconnect the wiring harness to the new sensor.

- Reconnect the battery and start your vehicle to check if the installation was successful.

Here is a table summarizing the tools you will need:

| Tool | Purpose |

|---|---|

| Wrench | To remove and install bolts |

| Socket Set | For various bolt sizes |

| Screwdriver | To disconnect wiring harness |

Replacing the crankshaft sensor can save you money. It also ensures your car runs efficiently.

Preventive Measures To Avoid Future Failures

Preventing crankshaft sensor failures is essential for engine health. Regular checks and early detection can save time and money. Follow the steps below to keep your crankshaft sensor in top shape.

Regular Maintenance

Regular maintenance is crucial. Always inspect the crankshaft sensor during routine checks. Clean the sensor to remove dirt and debris. Dirt can affect sensor performance.

Use a soft cloth and a mild cleaner. Avoid harsh chemicals. Check the sensor wires for wear and tear. Replace damaged wires immediately. Ensure all connections are tight and secure.

| Maintenance Task | Frequency |

|---|---|

| Inspect Sensor | Every 6 months |

| Clean Sensor | Every 6 months |

| Check Wires | Every 3 months |

| Replace Damaged Wires | As needed |

Early Detection Tips

Early detection can prevent serious issues. Watch for warning signs. If the engine misfires, check the crankshaft sensor. A faulty sensor can cause the engine to stall.

- Engine misfires

- Engine stalls

- Poor acceleration

- Check Engine Light

If you notice these signs, test the sensor. Use an OBD-II scanner for accurate results. Replace the sensor if needed. Early action can prevent costly repairs.

The Impact Of A Faulty Sensor On Engine Performance

The crankshaft sensor plays a critical role in engine performance. It monitors the position and speed of the crankshaft, ensuring optimal engine timing. A faulty sensor can drastically affect your vehicle’s efficiency and power.

Fuel Efficiency

A faulty crankshaft sensor disrupts the engine’s timing. This leads to poor fuel combustion. As a result, your vehicle consumes more fuel. You may notice frequent trips to the gas station. A bad sensor can also cause erratic fuel injection. This further decreases fuel efficiency.

Signs of reduced fuel efficiency include:

- Decreased miles per gallon

- Strong fuel smell from the exhaust

- Frequent engine stalls

Power Output

The crankshaft sensor is essential for proper engine power. When it fails, the engine may misfire. This results in reduced power output. You may experience sluggish acceleration and difficulty maintaining speed. Engine stalling is another common issue.

Symptoms of reduced power output include:

- Slow acceleration

- Engine misfires

- Frequent stalling

| Impact | Symptoms |

|---|---|

| Reduced Fuel Efficiency | Increased fuel consumption, fuel smell, stalling |

| Decreased Power Output | Slow acceleration, misfires, stalling |

Understanding The Costs

The crankshaft sensor plays a crucial role in your car’s engine. It monitors the position and rotational speed of the crankshaft. Replacing this sensor can involve various costs. Let’s break down these costs into two main categories: Replacement Parts and Professional Services.

Replacement Parts

Replacement parts can vary in price based on the vehicle model. Factors such as brand, quality, and where you buy it from also affect costs. Below is a simple table to give you an idea:

| Vehicle Type | Cost Range (USD) |

|---|---|

| Economy Cars | $30 – $70 |

| Mid-range Cars | $50 – $100 |

| Luxury Cars | $70 – $150 |

Buying a high-quality sensor can save you money. It lasts longer and performs better. Always check for warranties when purchasing the sensor.

Professional Services

Professional services are necessary for a proper installation. Labor costs can differ depending on the mechanic or auto shop. Here is what to expect:

- Labor Costs: Expect to pay between $50 and $100 per hour.

- Diagnostic Fees: Some shops charge a diagnostic fee of $50 to $100.

- Total Labor Time: Replacing a crankshaft sensor typically takes 1 to 2 hours.

Some mechanics offer packages that include both parts and labor. This can sometimes be more affordable. Always get a detailed quote before committing to services. Comparing prices from different shops can also help you save money.

Learning From Experience: Real-world Examples

Crankshaft sensors play a vital role in vehicle performance. Real-world examples help us understand their importance. Here, we will explore case studies and success stories. These examples show how crankshaft sensors solve problems and improve vehicle efficiency.

Case Studies

Real-life case studies provide insight into crankshaft sensor issues and solutions.

| Case Study | Problem | Solution | Outcome |

|---|---|---|---|

| Case Study 1 | Engine Misfire | Replaced Faulty Sensor | Smooth Engine Operation |

| Case Study 2 | Poor Fuel Efficiency | Sensor Calibration | Increased Fuel Economy |

| Case Study 3 | Engine Stalling | Sensor Realignment | Stable Engine Performance |

Success Stories

Success stories highlight how crankshaft sensors enhance vehicle performance.

- Improved Fuel Efficiency: A truck fleet reported a 10% fuel savings.

- Enhanced Engine Longevity: Proper sensor maintenance extended engine life by 20%.

- Reduced Emissions: Accurate sensor readings led to lower exhaust emissions.

These success stories illustrate the critical role of crankshaft sensors. They ensure smooth, efficient, and eco-friendly engine performance.

Credit: www.densoautoparts.com

Frequently Asked Questions

What Is A Crankshaft Sensor?

A crankshaft sensor monitors the position and rotational speed of the crankshaft, ensuring optimal engine performance.

How Does A Crankshaft Sensor Work?

It detects the crankshaft’s position and speed using magnetic or hall-effect sensors, sending data to the engine control unit (ECU).

Symptoms Of A Bad Crankshaft Sensor?

Symptoms include engine stalling, difficulty starting, misfires, and reduced fuel efficiency. Immediate diagnosis is crucial.

Can I Drive With A Faulty Crankshaft Sensor?

Driving with a faulty crankshaft sensor is risky. It can cause engine stalling and reduced performance.

How To Replace A Crankshaft Sensor?

Locate the sensor, disconnect the battery, remove the old sensor, install the new one, and reconnect the battery.

Conclusion

A faulty crankshaft sensor can affect engine performance and fuel efficiency. Regular maintenance helps avoid unexpected breakdowns. Replacing a damaged sensor ensures your vehicle runs smoothly. Understanding its role aids in better vehicle care. Keep your car in top shape with timely checks and replacements of the crankshaft sensor.