A pressure plate is a device that detects pressure or weight changes. It triggers an action based on the detected change.

Pressure plates are commonly used in various applications, from security systems to gaming controls. In security systems, they help detect unauthorized entry by sensing footsteps. Gamers use them in game controllers for an immersive experience. These devices are integral in industrial automation, where they monitor machinery and ensure safety.

Pressure plates enhance user interaction and system efficiency by providing immediate feedback. Their versatility and reliability make them essential in many fields. With advancements in technology, pressure plates continue to evolve, offering more precise and varied applications. Their simplicity and effectiveness ensure they remain a critical component in modern technology solutions.

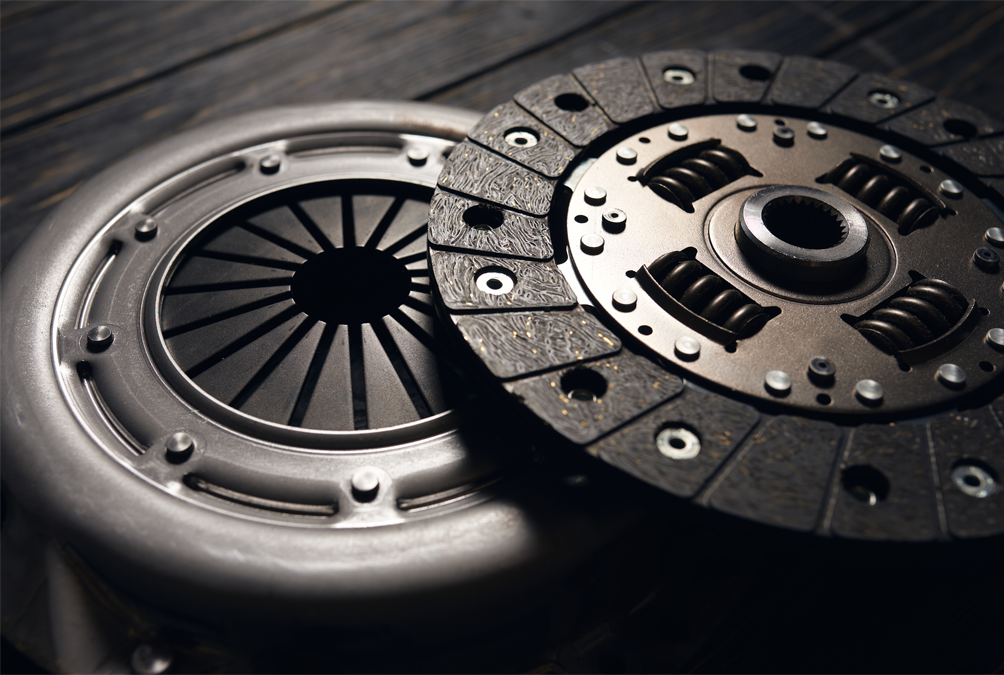

Credit: aftermarket.schaeffler.com

The Mechanics Of Pressure Plates

Pressure plates are essential in various industries. They detect force and respond accordingly. Understanding their mechanics can help in many applications.

How Pressure Plates Function

Pressure plates work by detecting force when something steps on or applies pressure. They then send a signal to a connected system. This system can trigger an action, like opening a door or turning on a light.

Sensors inside the plate measure the force applied. These sensors convert the force into an electrical signal. The signal can be used for different purposes based on the setup.

Types Of Mechanisms Involved

Different pressure plates use different mechanisms. Here are some common types:

- Mechanical Pressure Plates: These use springs and levers to detect force.

- Electrical Pressure Plates: These have electrical sensors for detecting pressure.

- Hydraulic Pressure Plates: Use fluid pressure to measure force and send signals.

| Type | Mechanism | Common Uses |

|---|---|---|

| Mechanical | Springs and levers | Simple machines, toys |

| Electrical | Electrical sensors | Smart homes, security systems |

| Hydraulic | Fluid pressure | Heavy machinery, industrial applications |

Historical Evolution Of Pressure Plates

The history of pressure plates is rich and fascinating. These devices have evolved significantly over time. Pressure plates have played a crucial role in various fields. From early inventions to modern developments, their journey is remarkable.

Early Inventions

The first pressure plates emerged in the 19th century. They were used in basic industrial applications. Early models were simple mechanical devices. They helped measure weight and force. Inventors experimented with different materials and designs. These early pressure plates were not very accurate. Yet, they laid the groundwork for future innovations.

| Year | Invention | Use |

|---|---|---|

| 1800s | Simple Mechanical Plates | Weight Measurement |

| 1850s | Improved Designs | Industrial Applications |

Modern Developments

Modern pressure plates are highly advanced. They use electronic sensors and digital technology. These advancements provide greater accuracy. Modern devices are used in various sectors. They include:

- Automotive industry

- Healthcare

- Consumer electronics

The introduction of smart pressure plates has revolutionized many fields. These devices can transmit data wirelessly. They are often integrated with IoT systems. The future of pressure plates looks promising with ongoing innovations.

Materials Used In Pressure Plate Construction

Understanding the materials used in pressure plate construction helps in choosing the right type for your needs. These materials determine the plate’s durability, efficiency, and overall performance. Let’s explore the common and innovative materials utilized in crafting pressure plates.

Common Materials

Traditional pressure plates often use materials that offer a good balance of cost and functionality. Here are some commonly used materials:

- Steel: Known for its strength and durability. Common in industrial settings.

- Aluminum: Lightweight and corrosion-resistant. Suitable for various applications.

- Brass: Offers good conductivity and resistance to wear.

- Plastic: Cost-effective and lightweight. Used in less demanding applications.

Innovative Materials And Technologies

Modern pressure plates leverage advanced materials and technologies to enhance performance. Some of these innovations include:

- Composite Materials: Combining different materials for enhanced properties.

- Ceramics: High resistance to heat and corrosion. Ideal for high-temperature environments.

- Carbon Fiber: Extremely lightweight and strong. Used in high-performance applications.

- Smart Materials: Integrate sensors and electronics for real-time monitoring.

Innovations in material science continually improve pressure plate technology, offering better performance and new functionalities.

Credit: www.quora.com

Design Considerations For Pressure Plates

Pressure plates are crucial in various industries. Their design determines performance and reliability. Key factors include size, shape, sensitivity, and calibration.

Size And Shape Variables

The size of a pressure plate affects its area of application. Larger plates can detect broader force ranges. Smaller plates provide precise readings in confined spaces.

The shape also plays a significant role. Common shapes include squares, rectangles, and circles. Each shape suits different applications. For example, circular plates are often used in medical devices. Rectangular plates work well in industrial settings.

| Shape | Common Applications |

|---|---|

| Square | General Use |

| Rectangle | Industrial |

| Circle | Medical Devices |

Sensitivity And Calibration

Sensitivity determines how well the plate detects pressure changes. High sensitivity is crucial in medical and scientific applications. Low sensitivity suits heavy industrial use.

Calibration ensures accurate readings. Regular calibration keeps the plate reliable. Calibration involves adjusting the plate to known standards. It compensates for wear and environmental changes.

- High sensitivity: Medical, scientific applications

- Low sensitivity: Industrial, heavy-duty applications

Calibration involves:

- Setting the plate to a zero baseline.

- Applying known weights.

- Adjusting readings to match expected values.

Applications In Everyday Life

Pressure plates are versatile devices that detect weight. They are found in many areas of our daily lives. Their applications range from home security to industrial uses. Let’s explore how these plates benefit us in various settings.

Home And Security

Pressure plates play a vital role in home security systems. They can be installed under doormats or rugs. When someone steps on them, they trigger an alarm. This helps in alerting homeowners about unexpected visitors.

Another use is in automated lighting systems. Pressure plates can turn on lights when someone walks into a room. This enhances convenience and saves energy. The lights turn off once the person leaves.

Pressure plates also help in monitoring the movement of pets. They can be placed near pet doors. This ensures pets’ safety by notifying owners of their movements.

Industrial Uses

In the industrial sector, pressure plates are used for various purposes. One key application is in automated machinery. Pressure plates can start or stop machines based on the presence of materials. This increases efficiency and reduces manual labor.

Another important use is in weight measurement systems. Pressure plates are used in weighing scales in factories. They provide accurate weight measurements of products. This is crucial for quality control and inventory management.

Pressure plates also help in ensuring worker safety. They can detect the presence of workers in hazardous areas. This triggers safety mechanisms to prevent accidents.

| Application | Benefits |

|---|---|

| Home Security | Alerts homeowners, enhances safety |

| Automated Lighting | Saves energy, increases convenience |

| Pet Monitoring | Ensures pets’ safety |

| Automated Machinery | Increases efficiency, reduces manual labor |

| Weight Measurement | Provides accurate measurements |

| Worker Safety | Prevents accidents |

Pressure Plates In Gaming And Entertainment

Pressure plates are versatile tools in the gaming and entertainment industry. They offer unique interactions and immersive experiences. They detect physical pressure and trigger various actions.

Video Games Mechanics

Pressure plates play a crucial role in video games. They often control traps, doors, and secret passages. Players must step on a plate to activate or deactivate these elements.

In some games, pressure plates are part of puzzles. They require strategic thinking to solve. This adds a layer of complexity and fun.

- Activate traps: Step on a plate to unleash traps.

- Open doors: Pressure plates can unlock hidden doors.

- Solve puzzles: Players must use pressure plates to complete puzzles.

These mechanics keep the game engaging and challenging. They make players think and react quickly.

Interactive Installations

Pressure plates are also found in interactive installations. These installations are popular in museums, art exhibits, and theme parks. They create interactive experiences for visitors.

When someone steps on a pressure plate, it triggers an event. This could be a light show, sound effect, or moving object. These interactions captivate and entertain audiences.

| Application | Effect |

|---|---|

| Museums | Triggers educational displays |

| Art Exhibits | Activates visual and sound effects |

| Theme Parks | Controls animatronics and ride elements |

Interactive installations offer a unique, engaging experience. They invite people to participate and explore. Pressure plates are key to making this happen.

Safety And Risk Factors

Understanding the safety and risk factors associated with pressure plates is crucial. These devices, often used in various applications, can pose potential hazards if not handled correctly. Proper safety measures can mitigate these risks and ensure safe usage.

Potential Hazards

Pressure plates can present several potential hazards if not used properly. These hazards include:

- Electrical Shock: Improper wiring or faulty components can cause electric shock.

- Mechanical Failure: Pressure plates may fail under high stress or load.

- Injury: Incorrect installation or use can lead to physical injuries.

- Fire Risk: Overheating or short circuits can cause fires.

A table summarizing these hazards can provide a clear overview:

| Hazard | Description |

|---|---|

| Electrical Shock | Improper wiring or faulty components |

| Mechanical Failure | Failure under high stress or load |

| Injury | Incorrect installation or use |

| Fire Risk | Overheating or short circuits |

Safety Measures

Implementing robust safety measures can significantly reduce the risks associated with pressure plates. Follow these guidelines:

- Regular Inspections: Conduct regular checks to identify wear and tear.

- Proper Installation: Ensure professional installation following manufacturer guidelines.

- Use Quality Components: Only use certified and high-quality parts.

- Training: Provide proper training for personnel handling pressure plates.

- Emergency Protocols: Establish and practice emergency response procedures.

By adhering to these safety measures, you can maintain a safe environment and minimize the risk of accidents related to pressure plates.

Credit: www.linkedin.com

Installation And Maintenance Tips

Proper installation and regular maintenance of a Pressure Plate ensure optimal performance. These tips will guide you through the best practices and procedures.

Installation Best Practices

Follow these steps to ensure a correct installation of your Pressure Plate:

- Read the Manual: Always refer to the manufacturer’s guide.

- Prepare the Surface: Clean the installation area thoroughly.

- Align Properly: Ensure the plate is level and centered.

- Secure Firmly: Use appropriate tools to fasten the plate.

- Check Connections: Verify all electrical connections are secure.

Adhering to these steps guarantees a stable and functional installation.

Routine Maintenance Procedures

Regular maintenance prolongs the lifespan of your Pressure Plate. Follow these procedures:

- Weekly Inspections: Check for any visible damage or wear.

- Monthly Cleaning: Wipe the surface with a damp cloth.

- Quarterly Testing: Test the plate’s sensitivity and responsiveness.

- Annual Servicing: Hire a professional to inspect and service the plate.

Here’s a table summarizing the maintenance schedule:

| Frequency | Task |

|---|---|

| Weekly | Visual inspection for damage. |

| Monthly | Surface cleaning. |

| Quarterly | Sensitivity and responsiveness tests. |

| Annually | Professional servicing. |

By following these tips, you ensure the Pressure Plate performs efficiently and lasts longer.

Innovative Uses Of Pressure Plates

Pressure plates have various modern applications. They are used in cutting-edge technologies. These applications span across different industries.

Energy Harvesting

Pressure plates can harvest energy from daily activities. For example, they can be installed in high-traffic areas. When people walk over them, they generate power. This power can be used for street lights or charging devices.

Below is a table showing the potential energy harvested from different activities:

| Activity | Energy Harvested (Watts) |

|---|---|

| Walking | 5 |

| Running | 10 |

| Jumping | 15 |

Data Collection

Pressure plates can collect valuable data. This data can be used for various purposes. For example, they can monitor foot traffic in malls. They can also track vehicle movement on roads.

- Foot traffic analysis

- Vehicle movement tracking

- Public transport usage

Data collected can help in urban planning. It can improve public safety by monitoring crowds. Retailers can also use this data to optimize store layouts.

Pressure Plate Customization

Pressure plates are versatile tools. They can be tailored to meet specific needs. Customization opens up a world of possibilities. From enhancing safety to adding a personal touch, you can do so much. Let’s explore how you can customize pressure plates.

Tailoring For Specific Needs

Every application of a pressure plate can be unique. Customization helps to meet exact requirements. Here are some ways to tailor pressure plates for specific needs:

| Application | Customization |

|---|---|

| Home Security | Add sensors and alarms. |

| Industrial Safety | Enhance durability and sensitivity. |

| Smart Homes | Integrate with home automation systems. |

Each application has unique requirements. Custom pressure plates ensure optimal performance.

Diy Pressure Plate Projects

Creating your own pressure plate can be a fun project. Here are steps to make a simple DIY pressure plate:

- Gather materials: cardboard, aluminum foil, wires, and tape.

- Cut two cardboard pieces of equal size.

- Cover one side of each piece with aluminum foil.

- Place a small spacer between the foil-covered sides.

- Connect wires to the aluminum foil.

- Tape the pieces together, leaving room for the wires.

Now, connect your pressure plate to a simple circuit. This can light up an LED or trigger a buzzer. DIY projects are great for learning and creativity.

Future Of Pressure Plate Technology

The future of pressure plate technology is fascinating. Innovations promise better performance and new applications. Let’s dive into what’s next.

Emerging Trends

Several emerging trends are shaping the future of pressure plates:

- Smart Sensors: Integrating IoT for real-time data collection.

- Wearable Technology: Pressure plates in shoes for health monitoring.

- Energy Harvesting: Generating power from footsteps on pressure plates.

Research And Development

Ongoing research focuses on improving material durability and sensitivity. New materials like graphene are being tested. These materials promise better accuracy and longevity.

Development teams are also working on reducing costs. Making pressure plates more affordable can broaden their applications. This includes use in hospitals, sports, and everyday consumer products.

| Aspect | Current State | Future Goals |

|---|---|---|

| Material | Silicone, Metal | Graphene, Advanced Polymers |

| Cost | High | Reduced |

| Applications | Limited | Widespread |

Regulatory And Legal Considerations

Understanding the regulatory and legal considerations for pressure plates is crucial. Businesses must comply with standards and laws to ensure safety and privacy. These considerations help avoid legal troubles and ensure product reliability.

Standards And Compliance

Pressure plates must meet specific standards and compliance guidelines. These standards ensure safety and performance. Here are some key standards:

- ISO 9001: Ensures quality management systems.

- ISO 13849: Focuses on machinery safety.

- IEC 61508: Covers functional safety of electrical systems.

Following these standards is not optional. They are mandatory for manufacturers. Meeting these standards ensures the product is safe and reliable.

Privacy And Legal Implications

Pressure plates can collect data. This raises privacy and legal concerns. Businesses must handle data responsibly. Here are some important points:

- Data Collection: Only collect necessary data.

- Data Storage: Securely store data to protect privacy.

- Data Sharing: Do not share data without consent.

Compliance with data protection laws is essential. Laws like GDPR and CCPA protect user data. Non-compliance can lead to hefty fines.

| Aspect | Regulation | Impact |

|---|---|---|

| Data Collection | GDPR | Limits data types collected. |

| Data Storage | CCPA | Requires secure storage. |

| Data Sharing | GDPR | Needs user consent. |

Businesses must stay updated on legal changes. Regular audits help ensure compliance. This protects the business and its customers.

Frequently Asked Questions

What Is A Pressure Plate?

A pressure plate is a device that detects weight or pressure.

How Does A Pressure Plate Work?

It triggers a response when pressure is applied.

Where Are Pressure Plates Used?

They’re used in security systems, gaming, and automation.

Can Pressure Plates Detect Weight?

Yes, they can measure and detect weight.

What Materials Are Pressure Plates Made Of?

They’re made from metals, plastics, or composites.

Are Pressure Plates Durable?

Yes, they are designed for long-term use.

How To Install A Pressure Plate?

Follow the manufacturer’s instructions for proper installation.

Conclusion

Pressure plates offer efficient solutions for various industries. They enhance safety, automation, and convenience. Implementing pressure plates can streamline operations and improve productivity. Stay ahead by integrating this technology into your systems. Discover the benefits and elevate your processes with pressure plates today.